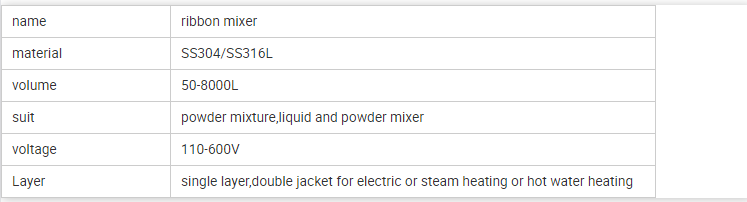

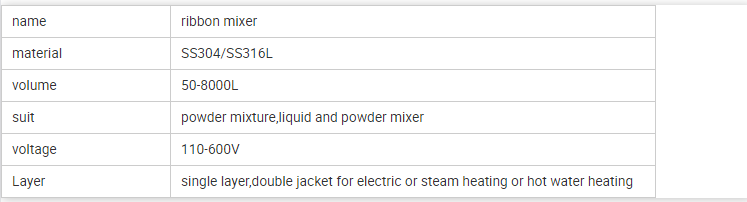

Ribbon Mixer

Brand: Flowtam

Material: 304(L) or 316(L)

Finish: Mirror or Matt Polish; Ra<0.8um

Certification: CE ISO9001:2000

The machine is composed of container, screw paddles and transitional parts; the screw paddle are generally made into 1 layer or 3

layers, the outer screw converge is the material to the centre front two sides, and the inner layer of screw conveys the material

to the two sides from the centre, so as to form convention mixing. The cubage can be made into rotundity, so the jacket can be

played in reaction and drying.

Feature

1.It is suitable for mixing materials of powder-powder and power-liquid, especially for paste,powder and thick materials, such as

putty, stone coatings, metal powders etc.

2.It is a new type of mixing equipment with high efficiency, high uniformity, high load factor,low energy consumption, low

pollution and little destruction to frangible material.

3.The major sections of a mixer are barrel, ribbon agitators, feeding ports, discharging port and driven unit.

4.Double ribbon mixer drive the material from two ends to centre through the help of the outer ribbon, while the inner ribbon push

the material from centre to two ends, thus, material achieve a high mixing effect at short time.

5.The ribbon mixer can be equipped with heating or cooling jacket if temperature control is required. We will add spraying or atomizing unit inside the tank.

PRODUCTS SHOW

PRODUCTS SHOW